The Handset is a standard NCE PowerCab which incorporates the command station function, which drives the transmitter module pictured left. It runs from a 12V battery pack which gives me true walk-around control.

The Handset is a standard NCE PowerCab which incorporates the command station function, which drives the transmitter module pictured left. It runs from a 12V battery pack which gives me true walk-around control.The traditional way of implementing radio control is to have a one-to-one relationship between a transmitter and a receiver. This is fine when you are flying a model plane and need to concentrate on it alone but I wanted to extend the advantages of DCC control which, in this context, would mean running two (or more) trains simultaneously from the same handset.

A DCC system is a broadcast system with one command station talking to any decoder that can hear it. Instead of the rails transmitting the control signals, I am using radio. I have found a transmitter and receiver pair from Radiometrix, the TX3 and RX3. These are available on various standard frequencies and I chose the 868-870 MHz band which is permitted in the UK for data transmission. It has four sub-bands, G1 to G4, the Radiometrix TX3A-869-64 transmits on 869.85 MHz and thus falls into the G4 band which permits a 100% duty cycle at no more than 5mW. This is enough for 25-75m inside a building and 100-300m outdoors. It can transmit at up to 64kbps which is more than enough for a DCC bit rate. Its input can be driven directly, with suitable attenuation, from any digital signal. The corresponding receiver module, the RX3A-869-64, has a digital output which is true data as fed to the transmitter. I had to convert this to be suitable for the decoder.

The Handset is a standard NCE PowerCab which incorporates the command station function, which drives the transmitter module pictured left. It runs from a 12V battery pack which gives me true walk-around control.

The Handset is a standard NCE PowerCab which incorporates the command station function, which drives the transmitter module pictured left. It runs from a 12V battery pack which gives me true walk-around control.

The principal challenge was to separate the power delivery from the signal transmission, which are superimposed in conventional DCC. I was unwilling to dissect a commercial decoder to experiment on, so I adapted Paul Harman’s DCC DIY motor and function decoders to split the rectifier and signal detector circuitry away from the signal processor and drivers.

The principal challenge was to separate the power delivery from the signal transmission, which are superimposed in conventional DCC. I was unwilling to dissect a commercial decoder to experiment on, so I adapted Paul Harman’s DCC DIY motor and function decoders to split the rectifier and signal detector circuitry away from the signal processor and drivers.

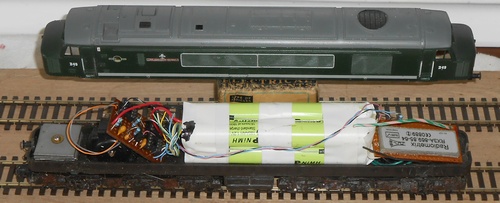

The latest prototype is shown in the picture here. The decoder PICs are not yet fitted. The eight Ni-Cad batteries just fit into the bodyshell and weigh more than the ballast weights I had to remove. Although they provide only 9.6 volts, the performance is adequate.

They are recharged through a socket in the bottom of the fuel tank. I did think about recharging through the wheels from a dedicated length of track in the station area (a refuelling berth) but, since I’m not cleaning the track outside, the wheels would also be dirty enough to make current collection unreliable.