Engineering Department Vehicles

Track and structures maintenance is one of those largely unseen activities but, since I’m a Railway Civil Engineer, it was a large part of my work. Anyone who has tried to travel by train at the weekend will have suffered the effects of engineering work but we always did try to keep this to a minimum. I have a few interesting Civil Engineer’s Department wagons around the system as described below.

Inspection

Inspection of the line and structures was and is a hierarchical activity. It starts at the bottom with the daily track-walking and (in BR days) ends at the top with the annual inspections led by the Regional General Manager and Chief Civil Engineer to decide which items should be included in the following years’ works programmes.

The Engineers’ Inspection Saloons were usually converted from an old non-corridor passenger coach and would be fitted out to enable a group of up to six people to spend several days out on site, travelling between the proposed work sites. They were fitted with observation windows at both ends and were propelled by the locomotive to allow a good view of the line. Facilities would include a couple of sleeping compartments, a well equipped galley kitchen and, until the Eltham Well Hall accident, a well stocked cocktail cabinet! To their credit, British Rail Managers led by example in clamping down on drinking on duty after that disaster. My model is the Bachmann LMS 50ft Inspection Saloon.

The Engineers’ Inspection Saloons were usually converted from an old non-corridor passenger coach and would be fitted out to enable a group of up to six people to spend several days out on site, travelling between the proposed work sites. They were fitted with observation windows at both ends and were propelled by the locomotive to allow a good view of the line. Facilities would include a couple of sleeping compartments, a well equipped galley kitchen and, until the Eltham Well Hall accident, a well stocked cocktail cabinet! To their credit, British Rail Managers led by example in clamping down on drinking on duty after that disaster. My model is the Bachmann LMS 50ft Inspection Saloon.

For local inspections by the area supervisors and inspectors, a Wickham Trolley was the favoured form of transport. Basic but very effective, these trolleys were seen all over the system and around the world in various guises. It was only in later years when the mobile gangs were introduced that the P-Way gangs started using road motor vehicles. This is a picture of one sitting on a typical lineside refuge somewhere in North Wales. My model will be static and will depict this sort of scene.

For local inspections by the area supervisors and inspectors, a Wickham Trolley was the favoured form of transport. Basic but very effective, these trolleys were seen all over the system and around the world in various guises. It was only in later years when the mobile gangs were introduced that the P-Way gangs started using road motor vehicles. This is a picture of one sitting on a typical lineside refuge somewhere in North Wales. My model will be static and will depict this sort of scene.

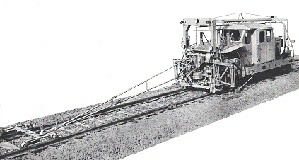

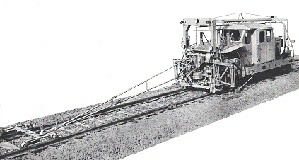

British Railways bought a total of 13 track geometry recording trolleys from Matisa of Switzerland between 1957 and 1967. They worked over all passenger lines and selected freight-only lines at intervals of between three and twelve months depending on the line classification. The trolley recorded directly onto a paper roll at up to 15 mph on plain line and 5 mph over S&C. When not recording, it could run under its own power at up to 40 mph. They became known also as the Neptune trolleys after a computer system was added to complement the paper trace. Read more about the trolley and its systems here. This trolley will be scratch-built and motorised. I’ve also found this short film at the British Pathé historical archive of one of the first prototypes in a very strange livery, being trialled on the Eastern Region.

British Railways bought a total of 13 track geometry recording trolleys from Matisa of Switzerland between 1957 and 1967. They worked over all passenger lines and selected freight-only lines at intervals of between three and twelve months depending on the line classification. The trolley recorded directly onto a paper roll at up to 15 mph on plain line and 5 mph over S&C. When not recording, it could run under its own power at up to 40 mph. They became known also as the Neptune trolleys after a computer system was added to complement the paper trace. Read more about the trolley and its systems here. This trolley will be scratch-built and motorised. I’ve also found this short film at the British Pathé historical archive of one of the first prototypes in a very strange livery, being trialled on the Eastern Region.

Maintenance and Renewal

During the 1960s and 70s, British Rail’s Taunton Concrete Depot supplied precast concrete components to most of British Railways. As well as the standard range of catchpit parts, S&T troughing, and so on, they also produced bridge beams to order, including a few to my own designs. The manager, Bill Copley, had become a true specialist at his job. He could be relied upon to turn out bridge units to consistently high quality, often to impossibly tight deadlines. The depot had a fleet of wagons modified especially for their needs which always had to be returned empty as soon as possible. This is a Cambrian Models kit.

During the 1960s and 70s, British Rail’s Taunton Concrete Depot supplied precast concrete components to most of British Railways. As well as the standard range of catchpit parts, S&T troughing, and so on, they also produced bridge beams to order, including a few to my own designs. The manager, Bill Copley, had become a true specialist at his job. He could be relied upon to turn out bridge units to consistently high quality, often to impossibly tight deadlines. The depot had a fleet of wagons modified especially for their needs which always had to be returned empty as soon as possible. This is a Cambrian Models kit.

The Mermaid wagon was the standard vehicle for distributing ballast for many years, it was designed to tip sideways to discharge new ballast onto the shoulders.

The Mermaid wagon was the standard vehicle for distributing ballast for many years, it was designed to tip sideways to discharge new ballast onto the shoulders.

As yet, I have no plans for tamping or lining machines or other engineering department wagons. However . . .

As yet, I have no plans for tamping or lining machines or other engineering department wagons. However . . .

. . . this little machine shown on the right is a Matisa automatic tamper dating from around 1960 and a model of this would be interesting to make. Matisa originally supplied tamping and other track maintenance machines to BR but Plasser increased their influence in the 1960s and, by the end of the decade, had gained the monopoly of supply.

Rail Cranes

There were two sorts of railway cranes – those intended for dealing with breakdowns and derailments, and those built for departmental maintenance and construction work. Before the days of the hydraulic crane, the breakdown cranes were sometimes employed by the civil engineer to assist with weekend bridge reconstruction work. It was a slightly risky option because the crane remained on-call and, if there was a derailment within its area, it could be summoned to attend. That would leave the engineer with a big hole in the track with no way of restoring the train service! Whilst working at area level, I made use of a 70 ton crane on a couple of occasions and, fortunately, we had quiet nights with no interruptions.

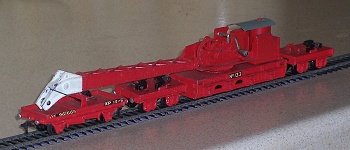

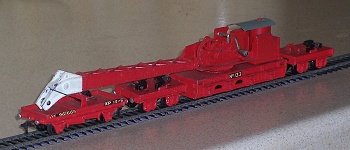

On the left, the original Hornby Dublo model based upon the Cowans Sheldon 45 ton breakdown cranes supplied to the LNER in 1940. The jib is foreshortened to help negotiate the HD 15" curves, the original No 133 was based at Cambridge. I also have (Triang) Hornby’s model which is based upon the Cowans Sheldon 75 ton breakdown cranes supplied to BR in 1962. It also has a foreshortened jib.

On the left, the original Hornby Dublo model based upon the Cowans Sheldon 45 ton breakdown cranes supplied to the LNER in 1940. The jib is foreshortened to help negotiate the HD 15" curves, the original No 133 was based at Cambridge. I also have (Triang) Hornby’s model which is based upon the Cowans Sheldon 75 ton breakdown cranes supplied to BR in 1962. It also has a foreshortened jib.

My thanks to Peter Tatlow for helping me correct errors in the information I had published previously on the cranes above.

Cowans Sheldon built a number of hand-operated yard cranes during the second war, BR used both 6½ and 10 ton versions. The Triang-Hornby model seems to be based on the 10 ton crane. It now comes in a rather gaudy yellow livery but earlier ones came in the red or brown livery more in keeping with the 1960s era. I have teamed mine up with a spare match truck from the original Hornby Dublo breakdown crane.

Cowans Sheldon built a number of hand-operated yard cranes during the second war, BR used both 6½ and 10 ton versions. The Triang-Hornby model seems to be based on the 10 ton crane. It now comes in a rather gaudy yellow livery but earlier ones came in the red or brown livery more in keeping with the 1960s era. I have teamed mine up with a spare match truck from the original Hornby Dublo breakdown crane.

The civil engineering department had a number of other specialised cranes, hoists and gantries for tracklaying. Some were adapted from commercially available road-going machines, some were specially designed, others were sourced from suppliers in mainland Europe.

Footnote

Bee-in-Bonnet Alert! On Tons and Tonnes

There is a difference between a ton and a tonne. A ton is the imperial unit of mass equivalent to 2240 pounds or 20cwt. A tonne is the metric unit of mass equivalent to 1000kg and roughly equivalent to 2204 pounds imperial. Many journalists use the expression “metric ton” which is a complete nonsense. The expression suggests to me that the journalist only partly understands the subject (so what’s new) and is trying to be clever. They are not!

Here endeth the rant.

• Back to rolling stock ...

The Engineers’ Inspection Saloons were usually converted from an old non-corridor passenger coach and would be fitted out to enable a group of up to six people to spend several days out on site, travelling between the proposed work sites. They were fitted with observation windows at both ends and were propelled by the locomotive to allow a good view of the line. Facilities would include a couple of sleeping compartments, a well equipped galley kitchen and, until the Eltham Well Hall accident, a well stocked cocktail cabinet! To their credit, British Rail Managers led by example in clamping down on drinking on duty after that disaster. My model is the Bachmann LMS 50ft Inspection Saloon.

The Engineers’ Inspection Saloons were usually converted from an old non-corridor passenger coach and would be fitted out to enable a group of up to six people to spend several days out on site, travelling between the proposed work sites. They were fitted with observation windows at both ends and were propelled by the locomotive to allow a good view of the line. Facilities would include a couple of sleeping compartments, a well equipped galley kitchen and, until the Eltham Well Hall accident, a well stocked cocktail cabinet! To their credit, British Rail Managers led by example in clamping down on drinking on duty after that disaster. My model is the Bachmann LMS 50ft Inspection Saloon. For local inspections by the area supervisors and inspectors, a Wickham Trolley was the favoured form of transport. Basic but very effective, these trolleys were seen all over the system and around the world in various guises. It was only in later years when the mobile gangs were introduced that the P-Way gangs started using road motor vehicles. This is a picture of one sitting on a typical lineside refuge somewhere in North Wales. My model will be static and will depict this sort of scene.

For local inspections by the area supervisors and inspectors, a Wickham Trolley was the favoured form of transport. Basic but very effective, these trolleys were seen all over the system and around the world in various guises. It was only in later years when the mobile gangs were introduced that the P-Way gangs started using road motor vehicles. This is a picture of one sitting on a typical lineside refuge somewhere in North Wales. My model will be static and will depict this sort of scene. British Railways bought a total of 13 track geometry recording trolleys from Matisa of Switzerland between 1957 and 1967. They worked over all passenger lines and selected freight-only lines at intervals of between three and twelve months depending on the line classification. The trolley recorded directly onto a paper roll at up to 15 mph on plain line and 5 mph over S&C. When not recording, it could run under its own power at up to 40 mph. They became known also as the Neptune trolleys after a computer system was added to complement the paper trace.

British Railways bought a total of 13 track geometry recording trolleys from Matisa of Switzerland between 1957 and 1967. They worked over all passenger lines and selected freight-only lines at intervals of between three and twelve months depending on the line classification. The trolley recorded directly onto a paper roll at up to 15 mph on plain line and 5 mph over S&C. When not recording, it could run under its own power at up to 40 mph. They became known also as the Neptune trolleys after a computer system was added to complement the paper trace.  During the 1960s and 70s, British Rail’s Taunton Concrete Depot supplied precast concrete components to most of British Railways. As well as the standard range of catchpit parts, S&T troughing, and so on, they also produced bridge beams to order, including a few to my own designs. The manager, Bill Copley, had become a true specialist at his job. He could be relied upon to turn out bridge units to consistently high quality, often to impossibly tight deadlines. The depot had a fleet of wagons modified especially for their needs which always had to be returned empty as soon as possible. This is a Cambrian Models kit.

During the 1960s and 70s, British Rail’s Taunton Concrete Depot supplied precast concrete components to most of British Railways. As well as the standard range of catchpit parts, S&T troughing, and so on, they also produced bridge beams to order, including a few to my own designs. The manager, Bill Copley, had become a true specialist at his job. He could be relied upon to turn out bridge units to consistently high quality, often to impossibly tight deadlines. The depot had a fleet of wagons modified especially for their needs which always had to be returned empty as soon as possible. This is a Cambrian Models kit. As yet, I have no plans for tamping or lining machines or other engineering department wagons. However . . .

As yet, I have no plans for tamping or lining machines or other engineering department wagons. However . . .

On the left, the original Hornby Dublo model based upon the Cowans Sheldon 45 ton breakdown cranes supplied to the LNER in 1940. The jib is foreshortened to help negotiate the HD 15" curves, the original No 133 was based at Cambridge. I also have (Triang) Hornby’s model which is based upon the Cowans Sheldon 75 ton breakdown cranes supplied to BR in 1962. It also has a foreshortened jib.

On the left, the original Hornby Dublo model based upon the Cowans Sheldon 45 ton breakdown cranes supplied to the LNER in 1940. The jib is foreshortened to help negotiate the HD 15" curves, the original No 133 was based at Cambridge. I also have (Triang) Hornby’s model which is based upon the Cowans Sheldon 75 ton breakdown cranes supplied to BR in 1962. It also has a foreshortened jib.

Cowans Sheldon built a number of hand-operated yard cranes during the second war, BR used both 6½ and 10 ton versions. The Triang-Hornby model seems to be based on the 10 ton crane. It now comes in a rather gaudy yellow livery but earlier ones came in the red or brown livery more in keeping with the 1960s era. I have teamed mine up with a spare match truck from the original Hornby Dublo breakdown crane.

Cowans Sheldon built a number of hand-operated yard cranes during the second war, BR used both 6½ and 10 ton versions. The Triang-Hornby model seems to be based on the 10 ton crane. It now comes in a rather gaudy yellow livery but earlier ones came in the red or brown livery more in keeping with the 1960s era. I have teamed mine up with a spare match truck from the original Hornby Dublo breakdown crane.